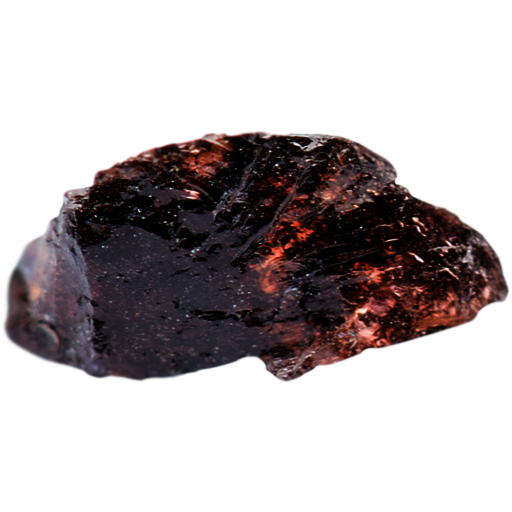

Electro-corundum

NKI angular electro corundum

Useable for a wide range of applications and changing blasting applications. Only limited usage on aluminium and stainless steel, due to the Fe-content and possible shadow formation.

Productinformation

Designation:

NKI angular electro corundum

Material:

Electro-corundum

Application:

Rough blasting,

Cleaning blasting,

Surface finish,

Cleaning buildup,

Paint stripping

Blasting systems:

Air-/injectorsystems

Material of the blasting material:

Steel,

Cast iron,

Wood,

Aluminum,

Non-ferrous metals,

Stainless steel

Grainsize:

F 12 = 1400 - 2000 µm

F 14 = 1180 - 1700 µm

F 16 = 1000 - 1400 µm

F 20 = 850 - 1180 µm

F 24 = 600 - 850 µm

F 30 = 500 - 710 µm

F 36 = 425 - 600 µm

F 40 = 355 - 500 µm

F 46 = 300 - 425 µm

F 54 = 250 - 355 µm

F 60 = 212 - 300 µm

F 70 = 180 - 250 µm

F 80 = 150 - 212 µm

F 90 = 125 - 180 µm

F 100 = 106 - 150 µm

F 120 = 90 - 150 µm

F 150 = 63 - 106 µm

F 180 = 53 - 90 µm

F 220 = 45 - 75 µm

F 230 = 34 - 82 µm

F 240 = 28 - 70 µm

F 280 = 22 - 59 µm

F 320 = 16 - 49 µm

F 360 = 12 - 40 µm

F 400 = 8 - 32 µm

F 500 = 5 - 25 µm

F 600 = 3 - 19 µm

F 800 = 2 - 14 µm

F 1000 = 1 - 10 µm

F 14 = 1180 - 1700 µm

F 16 = 1000 - 1400 µm

F 20 = 850 - 1180 µm

F 24 = 600 - 850 µm

F 30 = 500 - 710 µm

F 36 = 425 - 600 µm

F 40 = 355 - 500 µm

F 46 = 300 - 425 µm

F 54 = 250 - 355 µm

F 60 = 212 - 300 µm

F 70 = 180 - 250 µm

F 80 = 150 - 212 µm

F 90 = 125 - 180 µm

F 100 = 106 - 150 µm

F 120 = 90 - 150 µm

F 150 = 63 - 106 µm

F 180 = 53 - 90 µm

F 220 = 45 - 75 µm

F 230 = 34 - 82 µm

F 240 = 28 - 70 µm

F 280 = 22 - 59 µm

F 320 = 16 - 49 µm

F 360 = 12 - 40 µm

F 400 = 8 - 32 µm

F 500 = 5 - 25 µm

F 600 = 3 - 19 µm

F 800 = 2 - 14 µm

F 1000 = 1 - 10 µm

Hardness:

9 Mohs

Shippingunit:

-

Sacked

25 kg -

Big bag

1.000 kg

Are you looking for the right abrasive or would you like to optimize your blasting process?

Our experts will be happy to advise you personally:

Eisenwerk Würth GmbH

+ 49 (0) 71 36 98 98 - 0

info(at)eisenwerk-wuerth.de